Many of us in the fire service are getting back to the basics and this post will dive into Sawzall / reciprocating saw operations. I’ve included a bit of history, pictures, and some tips that will hopefully help contain your emotions prior to throwing this valuable tool to the side. Don’t be fooled, it takes practice to rip through the side of a bus, rear of a semi-tractor cab, or building construction materials quickly.

Many of us in the fire service are getting back to the basics and this post will dive into Sawzall / reciprocating saw operations. I’ve included a bit of history, pictures, and some tips that will hopefully help contain your emotions prior to throwing this valuable tool to the side. Don’t be fooled, it takes practice to rip through the side of a bus, rear of a semi-tractor cab, or building construction materials quickly.

History

I include this section primarily because I remember wondering why some people said sawzall, while others said reciprocating saw. After the explanation, I will use the term sawzall throughout the remainder of the post simply because sawzall is 9 letters shorter to type.

The reciprocating saw came into fashion by the Milwaukee Tool Company. The company patented the name “Sawzall” in 1951. Billed as the first portable electric hacksaw, the design has gone on by other tool companies under the name reciprocating saw. Hence, the interchangeable name used by many of us.

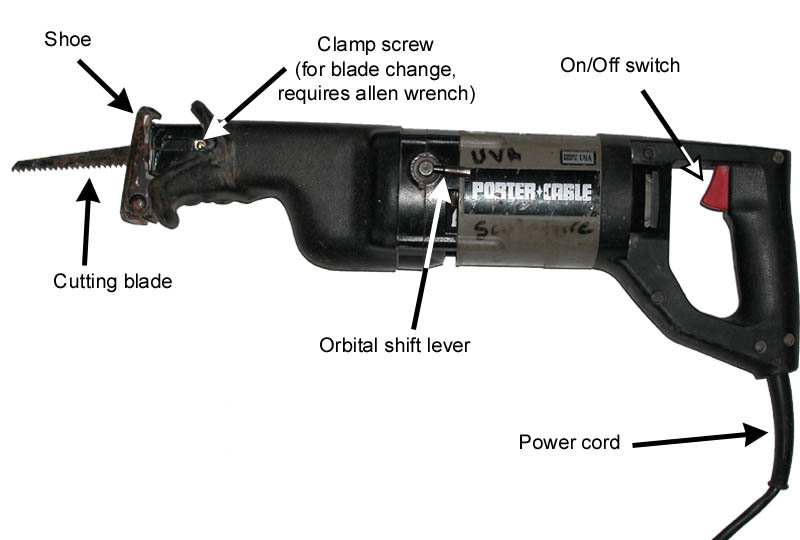

Common External Parts and Use

The sawzall is intended to replicate the motion of a hacksaw or jigsaw, but on a larger scale. It’s handle and blade placement make it comfortable for vertical cuts when used on wood, metal, plastics, or ceramics.

- adjustable shoe – helps guide and prevents kick back by allowing the sawzall to rest on the shoe as the blade cuts through the given material.

- orbital shift lever – some models come with this mode. To turn this function on there is a shift lever on the saw. When the saw is cutting in this mode the blade cuts in a push/pull manner plus in a slight circular motion.

- on/off trigger – all models have unloaded maximum speeds measured in Stokes Per Minute (SPM). The harder you squeeze the trigger, the faster it will move the blade. Some of the latest models on the market have maximum spm of 2700-3000.

- cutting blade stroke – this is the distance the blade moves forward on a single cutting stroke, which can vary from 3/4″ to 1 1/4″ depending on model and manufacturer.

*Note that many newer models have a clamp lever that doesn’t require an allen wrench.

[slideshow]

Tips

- Use the correct blade for the material being cut and have 25 spares on the rig.

- If possible set up your rigs for easy deployment of electric powered sawzalls. Battery power always seems to fail when you need it most.

- Get the SPM up prior to making contact with the material being cut. Violent kickback can quickly bend your blade beyond use.

- Let the saw do the work. With multiple layers of metal, boron, or high strength steal in modern day vehicles, you can not force the saw. Push in to set the shoe on the material more than down, which puts increased tension on the blade and locking mechanism. The result of to much tension on the blade will be a broken or released blade. At which point, it is not saws fault, but a design limit that prevents the motor from burning up.

- Know your saw.

Pass it on!

First Due Tackle Pass It On – Firefighter, Rescue & Extrication Training

First Due Tackle Pass It On – Firefighter, Rescue & Extrication Training